ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Sand Dryer

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

Product Introduction:

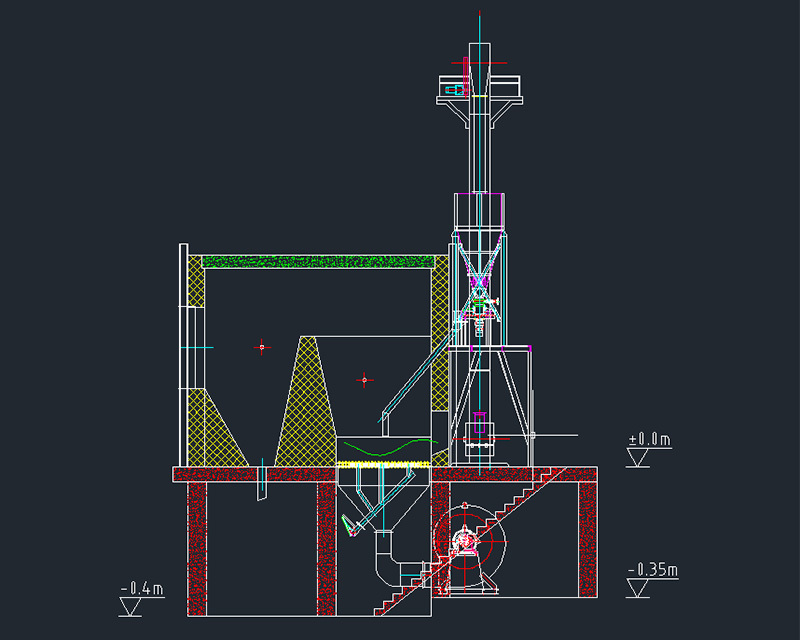

The Sand Dryer is engineered to handle various granular materials, including foundry sand, blast furnace slag, and industrial minerals. As a durable Sand Dryer from China, it features a unique three-cylinder design that maximizes heat exchange while minimizing space requirements. The Z-shaped material flow ensures thorough drying, reducing moisture content to as low as 0.5% with exceptional energy efficiency (up to 80% thermal efficiency). Its compact structure reduces overall length by 60% compared to traditional dryers, saving installation space and lowering infrastructure costs.

Built with heat-resistant alloy steel, this durable Sand Dryer from China offers 4x greater wear resistance than standard models, ensuring long-term reliability. The low outer-cylinder temperature (<60°C) protects downstream equipment like bag filters, while multiple drive options (gear, friction, or pinion) provide flexibility for different operational needs. Compatible with various heat sources (coal, gas, or oil), it’s a versatile solution for construction, cement, and chemical industries seeking consistent, low-maintenance drying performance.

HKSH three-cylinder dryer is mainly used for drying granular material flow within a certain range of humidity and particle size, such as yellow sand used in dry mortar industry, various specifications of sand used in foundry industry, blast furnace slag and small size clay used in building materials and cement industry, and used in chemical industry for the small granular materials that do not change chemically and are not afraid of high temperature and smoke pollution, and the moisture content of the dried materials can be up to 1-0.5% or less.

Sand dryer is through the single cylinder dryer of the single cylinder body is changed into a set of three cylinders, in order to shorten the size of the dryer body. When the machine works, the material and the hot air flow into the inner to outer cylinder in turn, after the Z-shaped reciprocating folding in the body, make full use of the thermal energy to dry the material and then unloaded. Three-cylinder dryer can make full use of waste heat, reduce heat loss, increase heat exchange area, so that the evaporation intensity per unit volume of the dryer is greatly improved.

Sand dryer main features

1, high technology, cylinder self insulation, thermal efficiency up to 80% (single cylinder dryer thermal efficiency is only 35%), than a single cylinder drying coal savings of 68%, the output is also relatively high.

2、Shorten the length of the whole machine by 60% compared with single cylinder dryer, which is favorable for process arrangement. Reduce the building area of the plant, save engineering investment of about 40%.

3、Adopting heat-resistant and wear-resistant alloy steel plate, which is 4 times more wear-resistant than ordinary steel plate. Long service life, easy maintenance.

4, high thermal efficiency, the outer cylinder temperature is lower than 60 ℃ (single cylinder dryer outer cylinder temperature up to 150 ℃), low export temperature, discharge temperature is lower than 60 ℃.

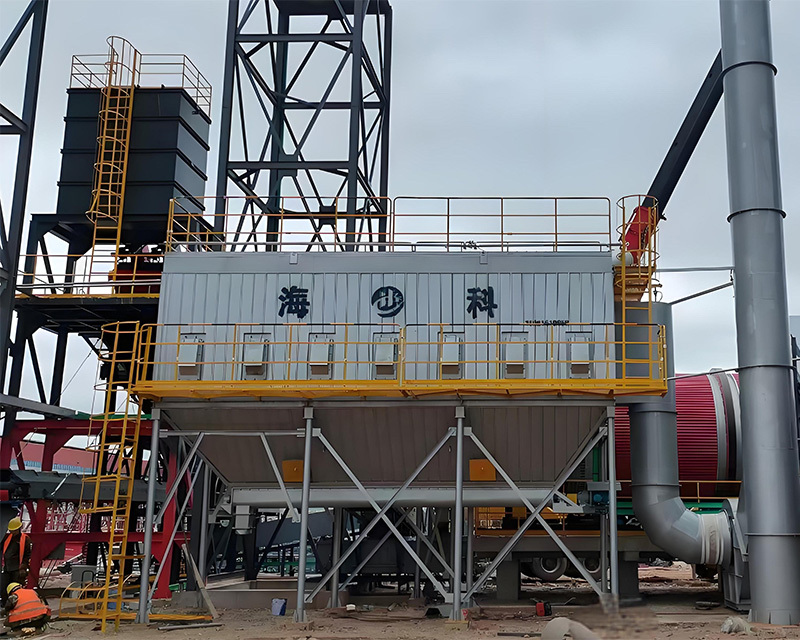

5、Low export temperature is conducive to the use of dust removal equipment for a long time, can be directly supporting the gas box pulse bag filter.

6、Civil construction investment is reduced by about 50%, and power consumption is reduced by 60%.

7, a variety of transmission methods, can choose friction transmission, gear transmission and pin gear transmission.

8、Hot air furnace can be equipped with boiling furnace, coal spraying furnace, hand-burning furnace, also used in fuel oil, gas furnace.

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية