ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Boiling Furnace Price

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

HKF type high temperature flue gas boiling furnace it is practical wide range, is the current domestic drying materials in many industries of the equipment, it adopts the fluidized bed combustion mode, the fuel in the furnace chamber through the role of high-pressure airflow layer up and down the role of the boiling state, to achieve the effect of enhanced combustion. Boiling furnace has high combustion efficiency, stable temperature, adequate heat supply, simple manufacture, convenient operation, flexible adjustment and remarkable energy-saving effect, which is the ideal supporting equipment for drying system of building materials, chemical industry, metallurgy, electric power and other industries.

HKF type high temperature flue gas boiling furnace has the following features

1、Good adaptability of fuel. Almost all kinds of poor quality coal can be burned, such as coal gangue, coal, poor quality bituminous coal, poor quality anthracite and so on.

2, the fuel in the furnace is fluidized boiling combustion, combustion is full, the burnout rate of 99% or more, the fuel loss is very low, energy saving is significant, compared with the hand-burning furnace, coal savings of more than 40%.

3、Fuel preparation is simple, slightly crushed to 0-8mm can be used in the furnace.

4、High degree of automation, low labor intensity, fast heating, long pressure fire time.

5、Automatic overflow slag discharge, no need for specialized slag discharge equipment. Ash activity is good, can be a good mixing material for comprehensive utilization.

6、Heat efficiency is 2-4 times of other furnaces, which can provide 450~1200℃ high temperature flue gas for the dryer in a stable and continuous way.

7、Low pollution. Fuel combustion is sufficient, the discharged SO, CO is greatly reduced, reducing public hazards.

8、The furnace body is equipped with an additional ash receiving device, which ensures the cleanliness of materials while drying fly ash and other non-polluting materials.

Main technical indicators

1、Furnace temperature 950±50℃, secondary temperature 850±50℃.

2、Combustion efficiency is more than 95%.

3, the calorific value of the fuel in 2500 kcal / kg or more, can be used in the furnace.

4、Isobaric box wind pressure: 6000-7000Pa.

HKF type high temperature flue gas boiling furnace outstanding structural features

Compared with the traditional boiling furnace, the following improvements have been made.

1, the use of equal pressure air box, large size porous air cap structure of the fluidized bed.

2, take a larger suspension chamber cross-sectional area, and the second combustion chamber, can be separated from the unburned fine coal particles, the second combustion, and further improve the combustion efficiency.

3、Set the overflow slag door on the fire door, automatic overflow slag discharge, no need for specialized slag discharge equipment.

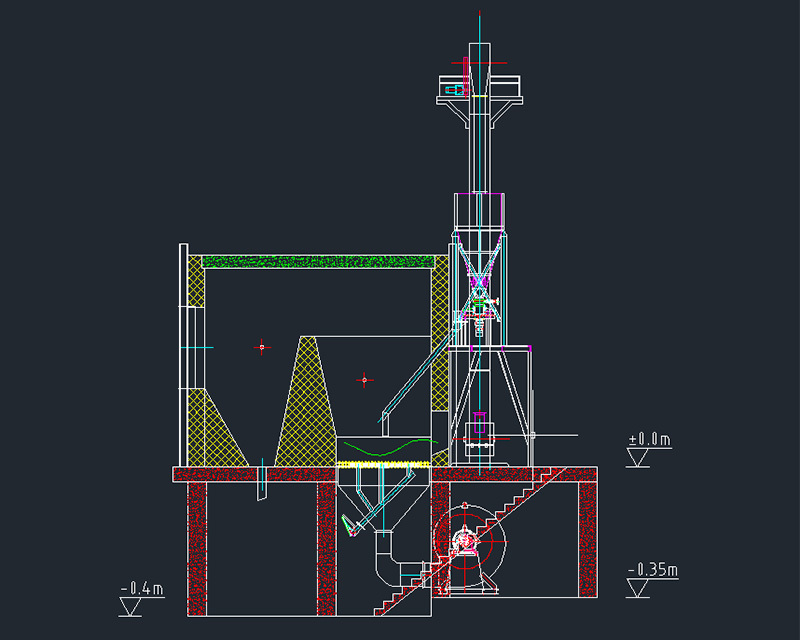

Furnace structure and technical performance parameters

The inner layer of the furnace body is made of clay refractory bricks, the outer layer is made of common building bricks, and the interlayer is filled with heat preservation materials. Its structure mainly consists of external angle steel furnace frame and channel steel tensioning column, internal air supply system, fluidized bed, suspension chamber and secondary combustion chamber and watch fire door (on the overflow of slag with small door), manhole door and other components.

Boiling furnace operating procedures

1. Baking furnace: new furnace body masonry is completed, carefully clear the furnace internal debris, check whether the air cap ventilation holes are clogged, and then start the blower, no-load operation for half an hour to determine the correct, in the wind cloth plate on the laying of 200-300mm thick sand, and then start the blower, observe the sand boiling situation, if the sand levels are clear, entrained without the flow of grooves, proving that the design requirements have been met.

Bake the furnace with dry wood and coal slowly baking, depending on whether the furnace body to stop smoking “sweat” or “steam” shall prevail, generally baking not less than 72 hours.

2. ignition: after the completion of the oven, with a fire hook will be discharged from the ash inside the furnace, to the furnace to add coal, add the amount of sand for the weight of 8-10% is appropriate, open the blower, the sand and coal blowing evenly, the formation of the substrate.

Spread a layer of firewood on the primer, ignite, burning, forming a thick layer of charcoal, hook out the unburned firewood, with a fire hook pounding, immediately start the blower, slightly open the blower valve, at this time you can see the charcoal layer of the surface of the slightly jumping, a layer of blue flames, and gradually increase the wind, the layer of material is stirred, showing a dark red wave of fire. Use the fire hook to gently stir the material layer, check whether there is any charcoal, such as charcoal, immediately remove. Close the fire door, continue to increase the wind, so that the entire furnace bed boiling, quickly start the disk feeder to the furnace coal, observe the flame presents a golden color, turn to normal operation.

3. Normal operation: normal production, the furnace temperature should be controlled at 900-1000 ℃, the flame shows a golden color. If the flame shows light white, the furnace temperature is high, should be appropriate to reduce the coal; if the flame is locally white, blinding, the furnace temperature is too high, should stop feeding coal, open the air volume, supplement the cold slag; if the furnace presents a dark red, the furnace temperature is too low, should be added to the coal.

4. Shutdown pressure fire: shutdown, stop feeding coal, and use the fire hook to check whether there are coke pieces, such as coke pieces discharged in a timely manner, and turn off the drum, induced draft fan, close the overflow of slag can be small door. The general fire time is 24 hours, * long can be pressed for 48 hours.

5. Re-start the fire: re-start the fire, depending on the circumstances of the appropriate addition of coal, the first slowly with a small wind to raise the fire, to be the primer presents a dark red wave of fire, quickly add wind, coal, and switch to normal production.

Safety regulations (warning)

1, open the blower, the furnace door must be closed, the operator deviated from the door to avoid flame burns.

2、The blower must be started with the door closed, and the operator must deviate from the door to avoid flame burns. After starting, slowly open the air door to the required air volume, is strictly prohibited within the drum machine with a load super start.

3、When burning coal, the dryer inlet temperature is less than 600 ℃ must set gas explosion-proof device.

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

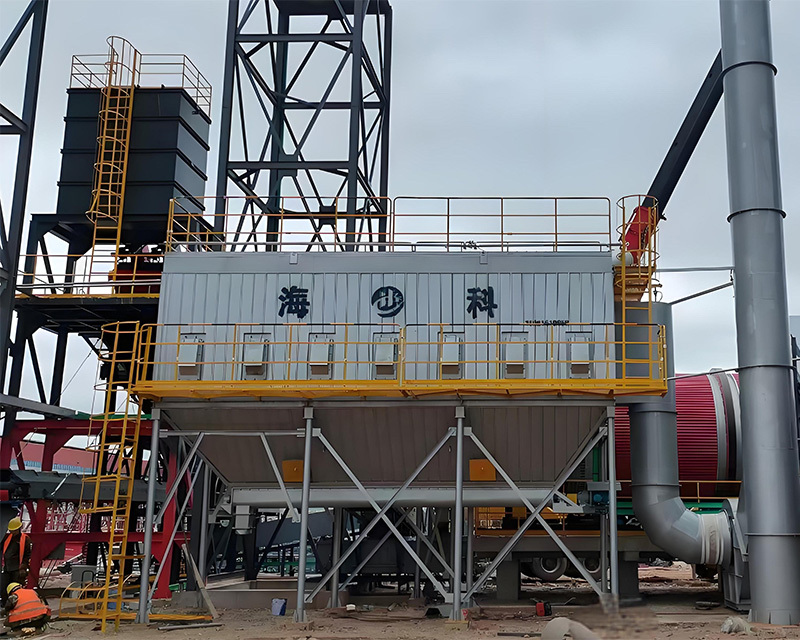

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية