ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Double locking dampers

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

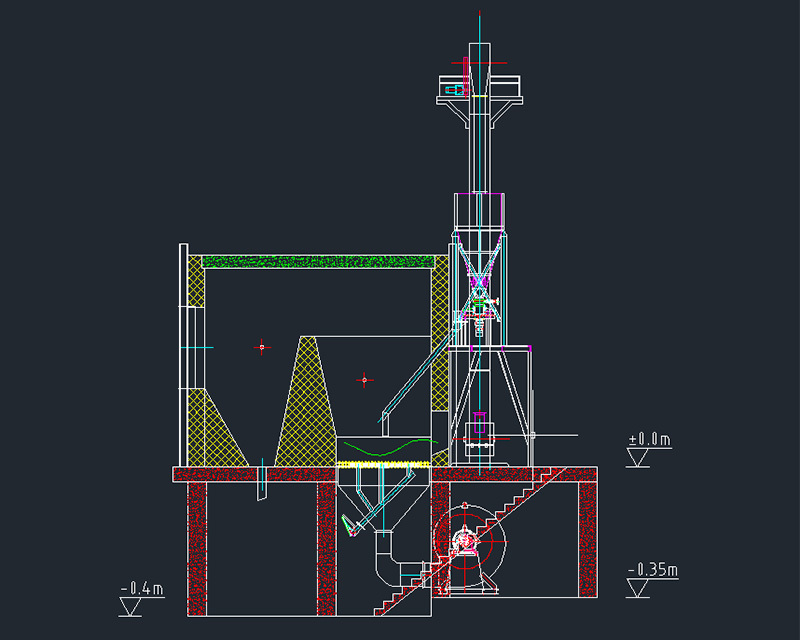

The double locking air valve belongs to mechanical equipment, especially involving a kind of double electric locking air valve used in cement production equipment. There are two types of double locking valves: single door and double door, which are widely used in building materials, metallurgy, chemical industry, electric power and other industries, as the discharging device of ash hopper of all kinds of dust removing equipments, and the discharging device of all kinds of mills, dryers, silos and other equipments to prevent the wild wind from blowing into them.

Working Principle

Driven by the reducer transmission rod through the crank, cam and connecting rod were driven by the upper and lower two drive shafts rotating, interacting with the opening, equipped with a lever system or tensile springs, to ensure that the valve plate reliably reset, to prevent the wild wind blowing into the system in accordance with the determined frequency of opening and closing to complete the system of unloading to be unloaded.

Structural features

Double lock wind valve has two sealing surfaces, commonly used mode gate valve of the two sealing surfaces to form a wedge, wedge angle varies with the valve parameters, usually 50, wedge-type plug valve gate can be made into a whole, called the rigid gate; can also be made to produce a small amount of deformation of the gate to improve its craftsmanship, to make up for the angle of the sealing surface in the processing of the bias generated by the gate is called the elastic gate Plug valve closure Plate valve closed, the sealing surface can only rely on media pressure to seal, that is, relying on the media pressure will be the sealing surface of the gate to the other side of the valve seat to ensure that the sealing surface of the sealing surface of the seal, which is the self-sealing. Most of the plug valves are forced sealing, that is, when the valve is closed, to rely on external forces to force the gate to the valve seat to ensure that the sealing surface of the sealing.

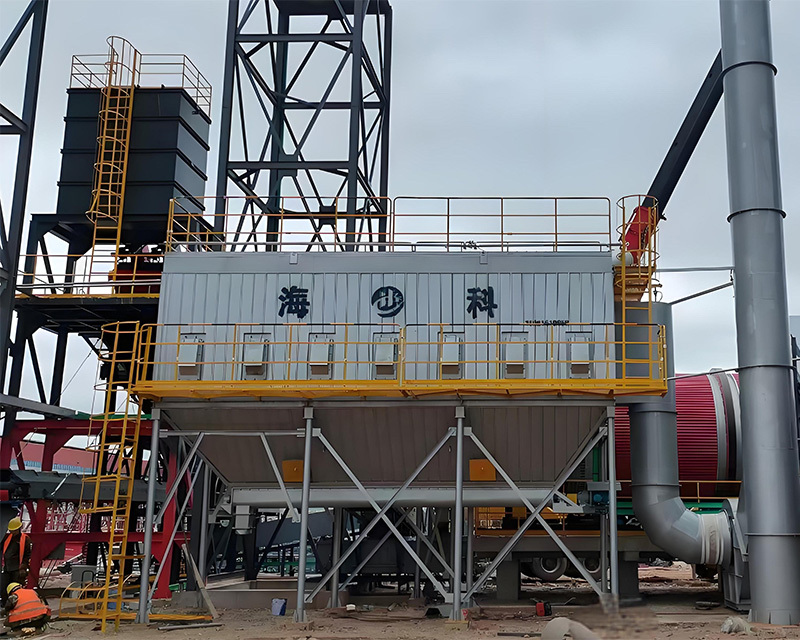

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية