ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Dry mortar production line price

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

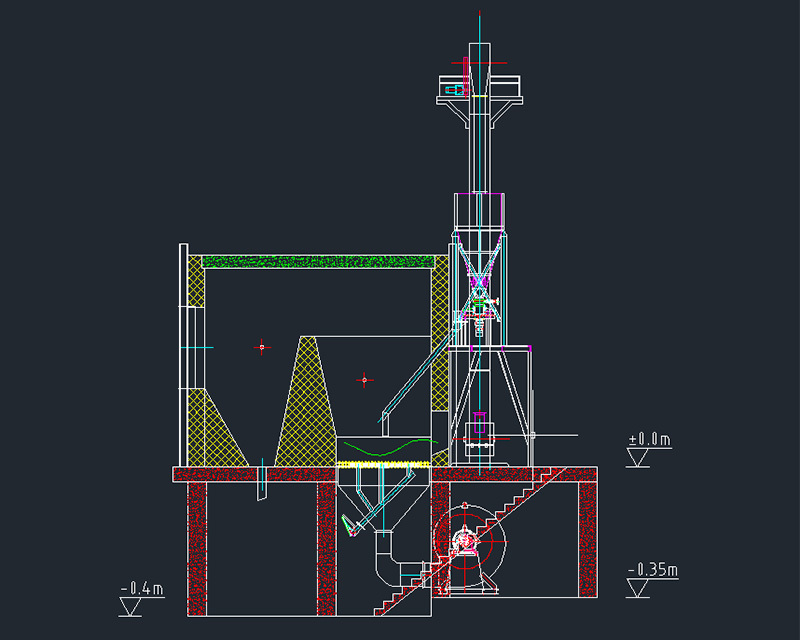

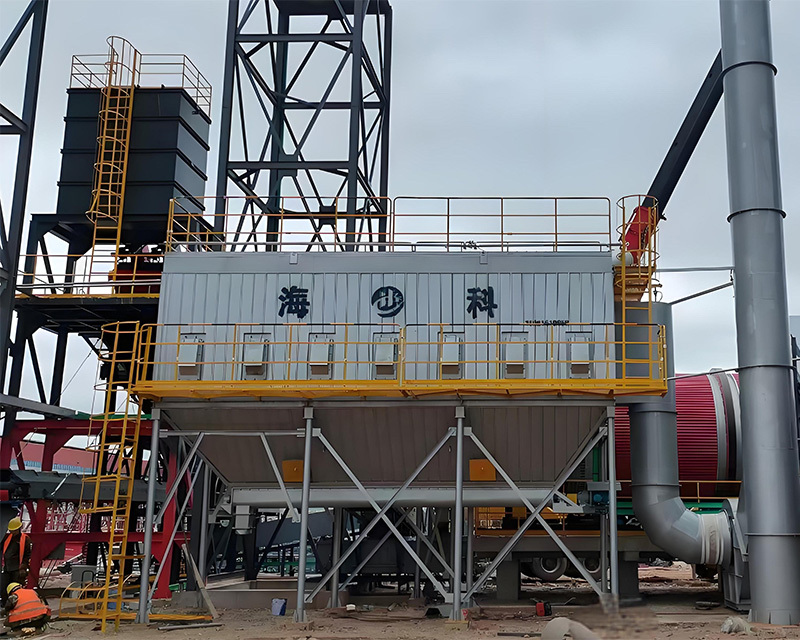

Dry mortar production line is mainly composed of dryer, dust collector, boiling furnace, elevator, tumbler screen, pre-mixing bin, small material bin, mixer, finished product bin, electric control cabinet, gas phase balance system. Cement and other large proportion of raw materials can be measured manually through the elevator into the pre-mixing silo, cellulose, glue powder and other small proportion of valuable masterbatch can be measured through the electronic scale into the admixture hopper.

Dry mortar production line manufacturers can adopt different programs according to the requirements and markets. Commonly used is the tower process layout, all the pre-treated raw materials will be elevated to the top of the raw material silo, the raw materials rely on their own gravity from the silo, through the computerized batching, screw conveyor metering, mixing and then to the packaging machine packaging bags or bulk into the bulk truck or into the finished product storage and other processes to become a product, all the production is operated by the centralized computer control system, the dosage is highly accurate, flexible, and the use of airtight production The system equipment makes the site clean, no dust pollution, and protects the health of workers. The structure of dry mortar production line equipment is easy to expand, so that the production capacity can be connected with the development of the market.

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية