ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

pulverized coal furnace

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

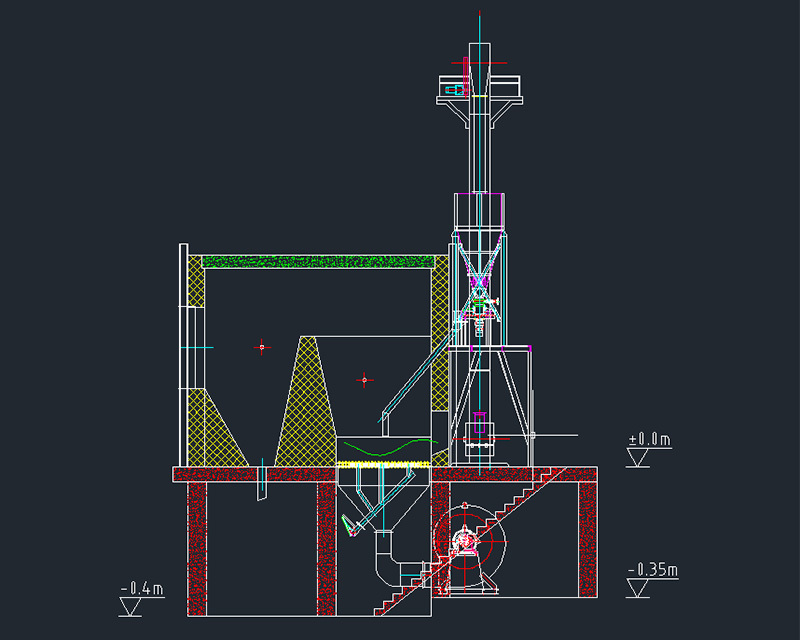

Pulverized coal furnace is a boiler equipment using coal powder as fuel. It has the advantages of rapid and complete combustion, large capacity, high efficiency, wide adaptability to coal types, easy to control and adjust and so on. The combustion of pulverized coal furnace is characterized by the fact that the fuel enters the combustion chamber together with the air and burns in a suspended state.

Coal pre-ground into a very fine coal dust, the surface area of contact with the air is greatly increased, so that combustion is strengthened. The temperature inside the pulverized coal furnace is also higher, so all kinds of coal can be burned efficiently in the pulverized coal furnace except the coal with very poor quality, and the combustion is more complete, and the combustion efficiency is also higher, about 88%-93%. It can be fully mechanized and automated. Pulverized coal combustion is the combustion method of almost all large coal-fired boilers.

The combustion equipment of pulverized coal furnace mainly consists of furnace, burner, ignition device and other parts. The pulverized coal is conveyed into the furnace chamber by the primary air through the burner, and the secondary air is introduced into the furnace chamber through the secondary air ring duct or secondary air opening of the burner.

The mixture of pulverized coal and air enters the furnace chamber, and after preheating, drying, volatilization and analysis, it starts to catch fire and burn at a certain distance from the burner outlet. Ash formed after the combustion of pulverized coal, a small portion of the particles of the coarser ash to form ash, falling into the cold ash bucket, cooled to solid ash, regularly or continuously to be excluded; the vast majority of particles of the finer ash is taken away by the flue gas, usually this part of the ash is called fly ash.

Coal powder in the furnace chamber to stay a very short time, only 1-2 s. In such a short period of time to ensure that the coal powder in the furnace burned out, must strengthen the combustion, the supply of appropriate amount of primary and secondary air, in order to shorten the combustion of the preparatory stage and to create good combustion conditions. The main role of the primary air of pulverized coal furnace is to transport pulverized coal to the furnace and ensure the ignition of volatile matter combustion. The role of the secondary air, one is to supplement the amount of air; the second is to make the pulverized coal and air mixed evenly, to ensure complete combustion of fuel. Therefore, in the operation of the operation, to reasonably adjust the ratio of the first and second wind and mixing time, in order to reliably guarantee the safe and economic operation of the boiler.

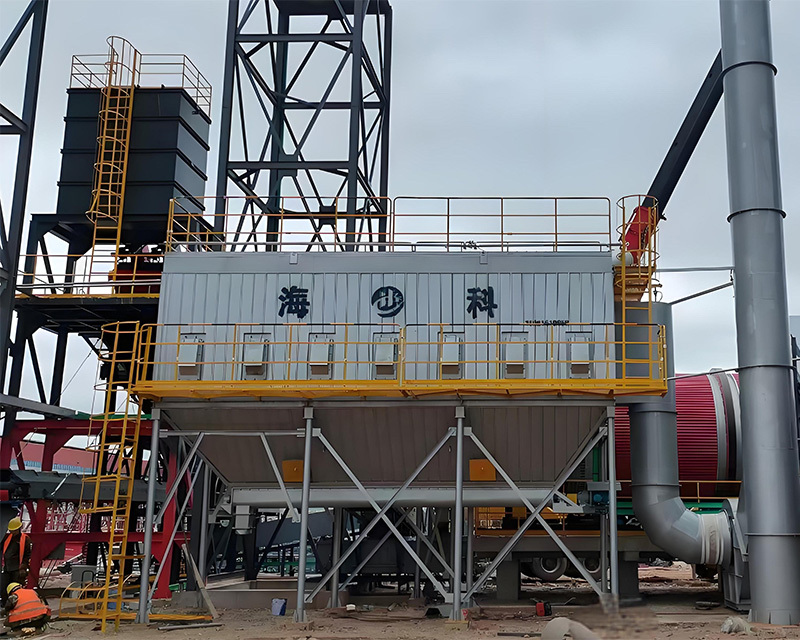

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية