ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Compound Powder Separator

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

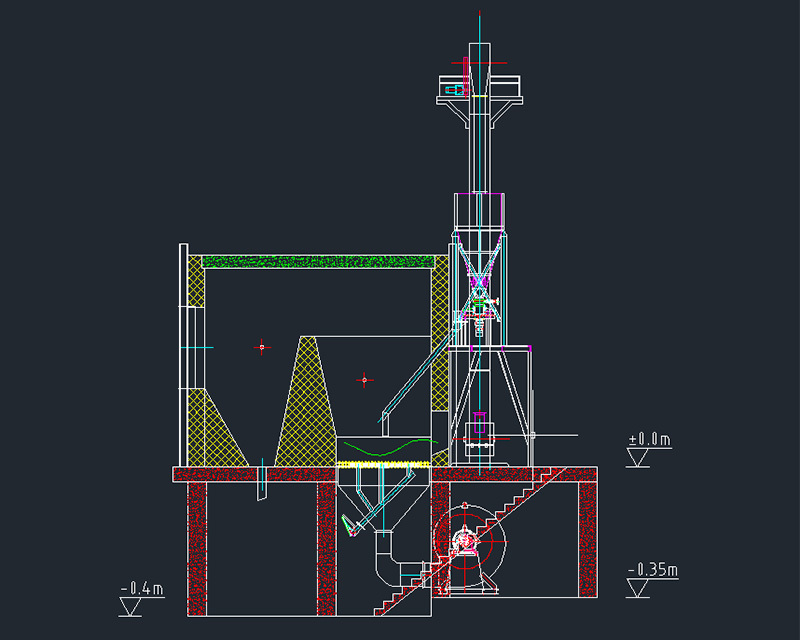

The material is fed from the upper inlet to form a material curtain, and the airflow from the inlet passes through the material curtain and realizes contact with the material. In the powder selecting area, it is dispersed by the stepped inclined folding plate set in the entrance side and exit side of the powder selecting machine. The materials collide back and forth at the ends of the folding boards on both sides to achieve the effect of dispersing the material pieces, fully exposing the fine powder and prolonging the residence time of the material curtain in the powder selecting area. The coarse material is discharged along the guide plate, and the gas with material is discharged from the air vent into the powder selector to separate the material and gas. The folding plate has the function of guiding flow and material. Compound powder selecting machine relies on wind power to lift, convey and classify with high precision.

There is no rotating part inside, mainly composed of grating plates arranged in trapezoidal shape, the materials to be sorted flow down in a trapezoidal shape on a set of rungs, and there is a sorting airflow on the rungs, which separates the fine powder from the materials and conveys it to the fine powder outlet, and the particle size distribution and flow rate of the discharged coarse and fine powder can be regulated through the adjustment of the sorting airflow. It improves the stability of the compound powder selector, and the structure of the powder selector is simple, easy to install and maintain, with little wear and less maintenance.

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

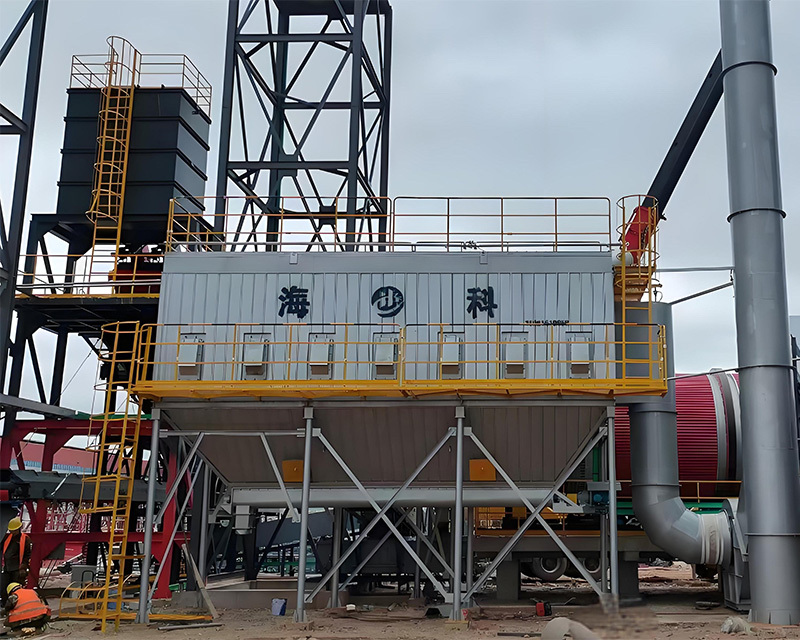

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية