ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Triple Separation Powder Separator

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

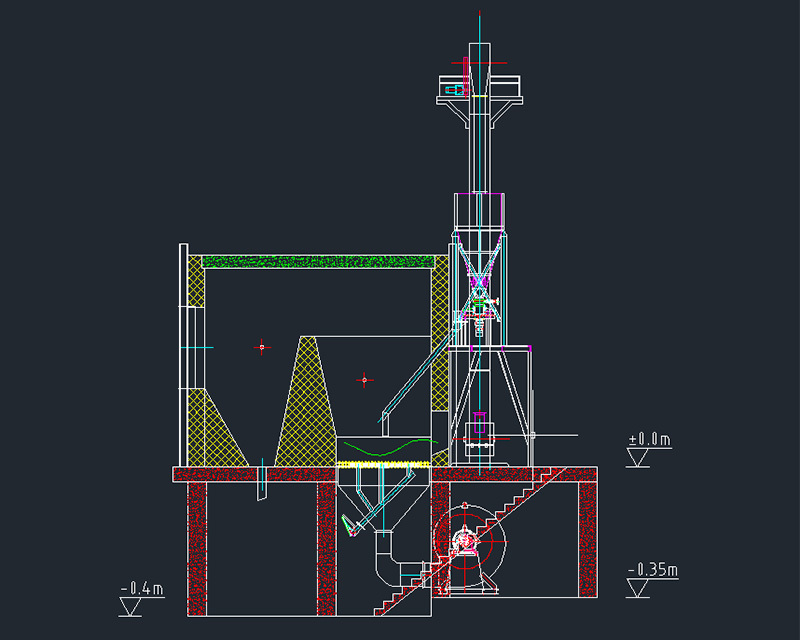

T-Sepax three-separation powder selector is a high-tech product of our company based on the principle of powder selecting and adopting the aerodynamic analysis method. It absorbs the grading advantages of O-Sepa powder separator and retains the characteristics of traditional powder separator using four cyclone dust collectors to collect the finished products under positive pressure working condition, therefore, this product has simple system configuration, low investment, high powder separating efficiency, and it can greatly increase the output of the mill. Lead the new trend of powder selecting machine technology revolution.

Three separation powder selecting machine product description

1, the material “one into three”, that is, “coarse powder (d>150um), coarse powder (60um <d<150um), fine powder”. The primary powder separation separates the coarse particles in the mixed powder, and the secondary powder separation is completed in the annular space formed by the guiding blades and vertical rotating cage, so the grading precision is particularly high and the sorting efficiency is higher.

2, T-Sepax three separation powder selector with similar size centrifugal, cyclone, rotor type selector compared to the handling capacity and powder selector compared to the processing capacity and efficiency of powder selection have been greatly improved, and thus more adaptable to the needs of large-scale production. Reasonable structure allows the powder selecting air volume, output and feeding volume to change in a wide range without affecting the powder selecting efficiency. Its grading performance is very stable.

3、Scientific grading principle. Combined with a variety of powder selecting principle, the aerodynamic analysis method is adopted to optimize the design of the flow field of the whole pulse dust collector and three-cylinder dryer, which makes the resistance of the equipment reduced, and the energy saving and consumption reduction is very obvious. The airflow in the rotor only rises and does not rotate relative to the rotor, utilizing the airflow into the rotor due to the role of momentum reduces the driving force on the rotor, saves the driving power and reduces the wear and tear. The material is selected twice, and the grading accuracy is higher and more precise.

4、The main shaft of powder selecting machine adopts stepless speed regulation. The fineness adjustment is convenient, sensitive and reliable, and the adjustment range is wide.

5、Re-optimized design of the powder selecting area and the space range of the lifting area, making full use of the main body of the space to increase the ratio of material to air and improve the efficiency of powder selecting.

6, powder selecting machine wear-resistant parts, such as spreading disk, cyclone worm angle, guide blade and rotor grading blade, etc. are made of wear-resistant materials or anti-abrasive process, and its wear rate is extremely low. Adopting new manganese plate as inner liner effectively prolongs its service life.

7, the spindle bearing seal adopts new design scheme, which effectively solves the two problems of bearing dust and lubricating oil leakage, and effectively prolongs the service life of the lower bearing.

8、When designing the foundation of powder selector, mechanical damping principle is adopted, so that the resonance frequency of powder selector and foundation is not close to the intrinsic frequency of powder selector and intrinsic frequency of foundation, which fundamentally solves the vibration problem of powder selector that has long been troubling the manufacturers.

9, coarse powder pipe, medium coarse powder pipe and cyclone are using double locking valve, greatly reducing the system leakage rate to overcome the previous powder selector operation in the dust defects.

Haike Strength

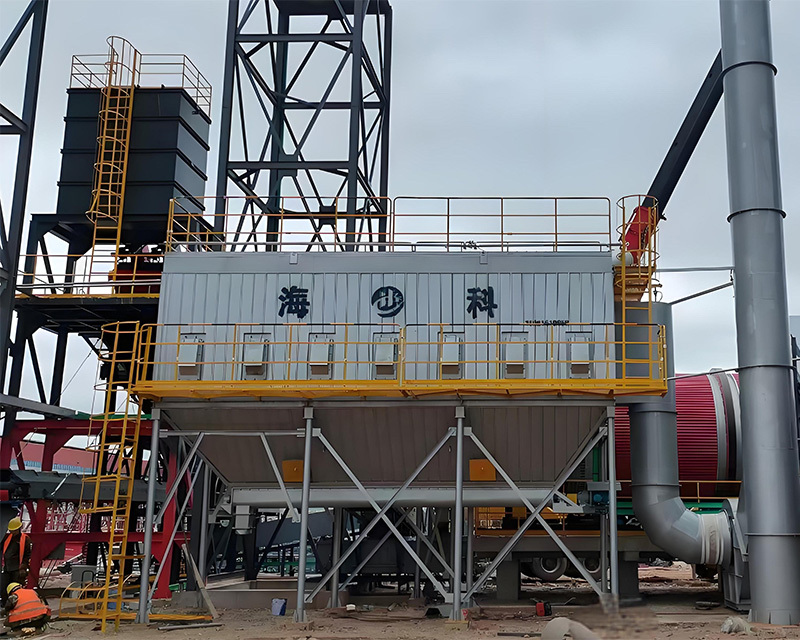

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية