ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

High temperature SCR denitrification reactor

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

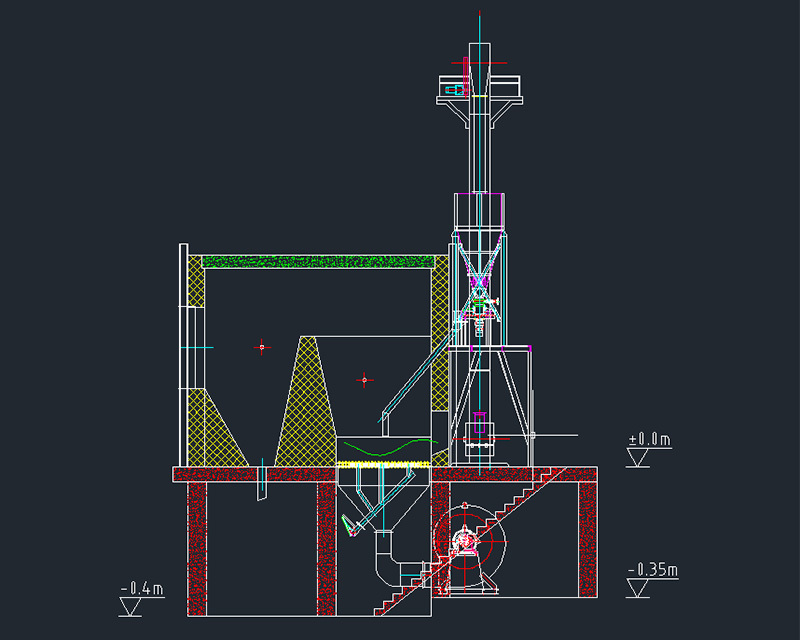

High temperature SCR denitrification reactor is the core equipment of selective catalytic reduction denitrification technology, which is used for catalytic reduction treatment of nitrogen oxides (NOx) in high temperature flue gas. The high temperature SCR denitrification reactor is based on SCR technology, by spraying reductant (such as ammonia NH₃) into the flue gas, the NOx in the flue gas is reduced to nitrogen (N₂) and water (H₂O) under the action of catalyst.

Application Characteristics

High temperature SCR denitrification reactor has the following characteristics in industrial applications:

1, denitrification:

Under the appropriate temperature, the denitrification efficiency can reach 80%-95%, meeting the strict environmental emission standards.

2、Adapt to high temperature flue gas:

Without flue gas cooling, it can directly deal with the high temperature flue gas at the exit of the economizer, reducing the energy consumption of the system.

3、Catalyst anti-sulfur poisoning:

The high temperature catalyst has better resistance to SO₂ in the flue gas, suitable for high sulfur fuel conditions.

4, system stability:

Modular design and redundant configurations (e.g. spare catalyst layer, bypass system) improve system stability.

5、Maintenance cost:

Catalyst life is usually 2-4 years and needs to be replaced regularly; soot blowing system and ammonia injection system need regular maintenance.

Typical application scenarios

High temperature SCR denitrification reactor is widely used in:

Coal-fired power plants: to treat NOx emissions from boiler flue gas.

Cement kilns: adapting to high-temperature and high-dust working conditions, realizing ultra-low emission.

[...]

[...]

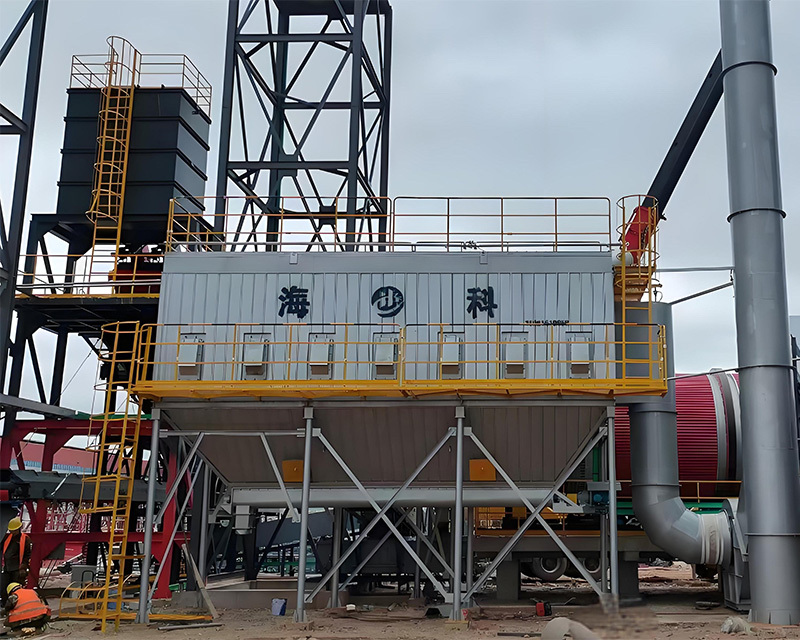

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية