ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

Wet desulfurization tower

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

Wet desulfurization tower is a kind of core equipment used for flue gas desulfurization (FGD), which adopts wet desulfurization technology and realizes desulfurization through the chemical reaction between liquid absorbent and sulfur dioxide (SO₂) in flue gas.

Working Principle

Wet FGD tower utilizes liquid absorbent (such as limestone slurry, lime slurry or seawater) for gas-liquid contact reaction with SO₂ in flue gas. The flue gas enters from the bottom of the tower, the absorbent is sprayed down from the top of the tower, both of them are in full contact in the tower, SO₂ is absorbed and chemical reaction occurs to generate sulfite or sulfate.

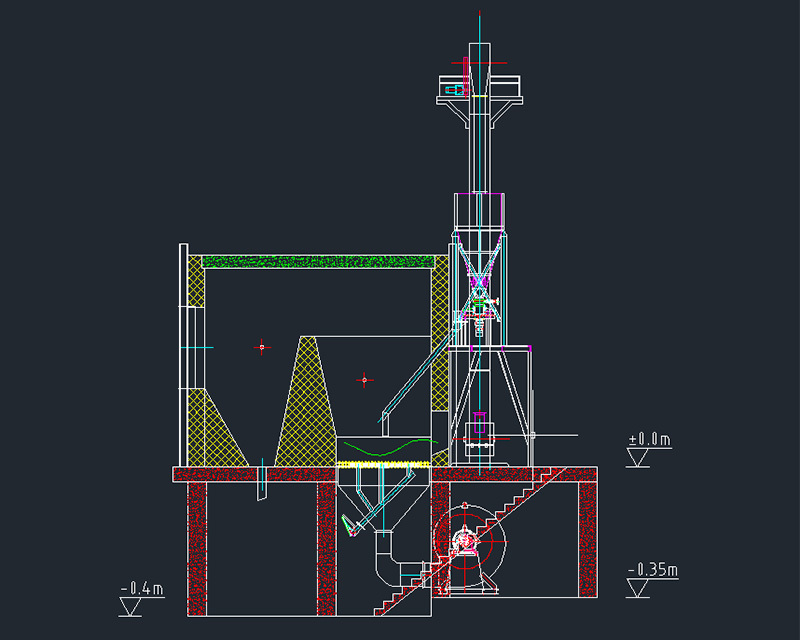

System Composition

Wet desulfurization tower system usually includes the following parts:

Absorption tower: the core equipment, where the flue gas and absorbent undergo gas-liquid contact reaction.

Slurry Recycling System: Includes a slurry tank, a recycling pump and a spraying layer to ensure that the absorbent is recycled.

Oxidation system: Forced oxidation of sulfite to sulfate by air to generate gypsum.

Mist eliminator: removes liquid droplets in the flue gas to prevent the phenomenon of “gypsum rain”.

By-product treatment system: Gypsum dewatering equipment (e.g. vacuum belt dewatering machine) dewater the gypsum slurry for storage or comprehensive utilization.

Wastewater treatment system: treat the desulfurization wastewater to achieve standard discharge or reuse.

Technical features

High desulfurization efficiency: the efficiency of desulfurization can reach more than 90%, which is suitable for high sulfur coal areas and occasions with strict environmental protection requirements.

Mature technology: limestone-gypsum method is a widely used wet FGD technology with stable operation.

Resourcefulness of by-products: gypsum can be used in building materials, cement retarder and other fields to realize waste utilization.

Strong adaptability: it can deal with high concentration of SO₂ flue gas, and has good adaptability to coal type and load change.

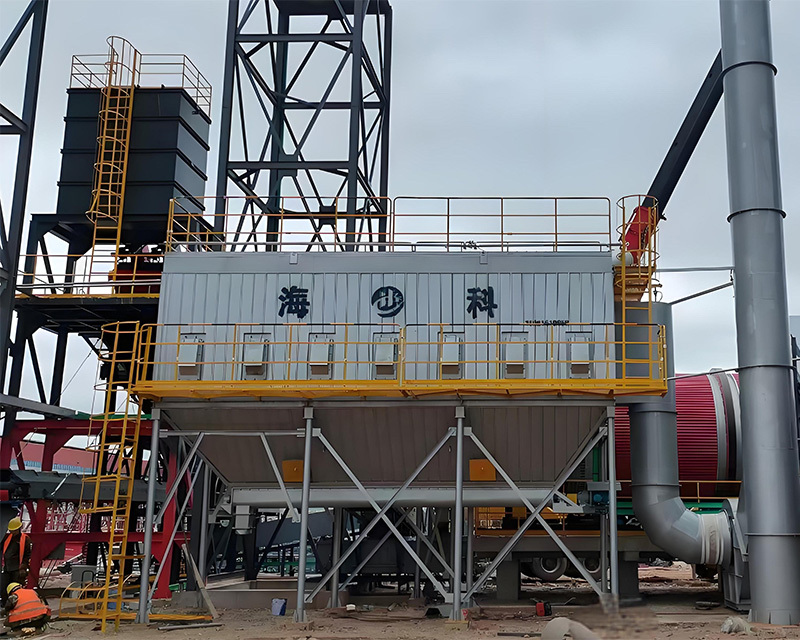

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية