ENERGY SAVING AND ENVIRONMENTAL PROTECTION EQUIPMENT AND ENGINEERING GENERAL CONTRACTING

wet desulfurization

Categories:

We are a company specializing in the research and development of energy-saving and environmental protection equipment and engineering general contracting.

keywords:Combustion furnace丨Dryer丨Dust collector丨Separator

Tel:

Email:

Product introduction

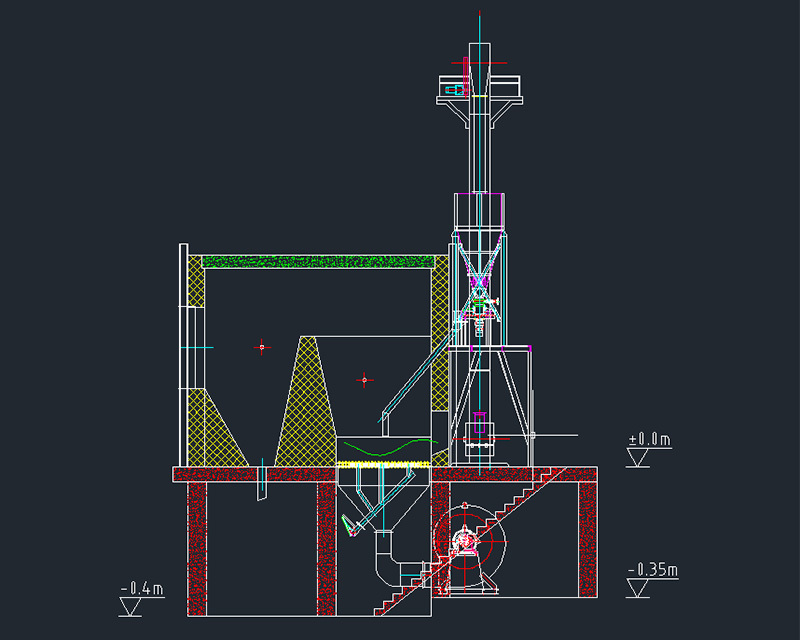

Wet desulfurization is a flue gas desulfurization technology, mainly used to remove sulfur dioxide (SO₂) produced during the combustion process of coal, fuel oil and other fuels, in order to reduce the emission of air pollutants.

Working Principle

The core of wet FGD is through gas-liquid reaction, using alkaline absorbent (such as limestone slurry, lime slurry or seawater) to chemically react with SO₂ in the flue gas to produce stable salts (such as calcium sulfate or sulfate), so as to achieve the purpose of desulfurization. The specific process includes:

Absorption stage: the flue gas enters the absorption tower and comes into full contact with the sprayed absorbent, SO₂ is absorbed and sulphite is generated.

Oxidation stage: sulfite is oxidized to sulfate (e.g. gypsum) in the absorption tower to improve the stability of by-products.

Dehydration stage: the gypsum slurry discharged from the absorption tower is concentrated and dewatered to form gypsum with less than 10% water content, which is easy to store and utilize.

Flue gas reheating: The temperature of flue gas after desulfurization is lowered, which needs to be heated by heat exchanger and then discharged to avoid plume and corrosion problems.

Technical features

1、High desulfurization efficiency: the desulfurization rate is usually higher than 90%, which is suitable for large coal-fired power stations and industrial flue gas treatment.

2, mature technology: wet desulfurization technology is mature in development and stable in operation, occupying a dominant position in the desulfurization market.

3、Resourcing of by-products: FGD by-products (e.g. gypsum) can be used in building materials, cement retarder and other fields to realize waste utilization.

4, adaptable: can deal with high concentration of SO₂ flue gas, good adaptability to coal type and load changes.

Application fields

Wet desulfurization is widely used in the following industries:

Power industry: flue gas desulfurization of coal-fired power plants to reduce SO₂ emissions.

Iron and steel industry: flue gas desulfurization of sintering machine and coke oven.

Chemical industry: flue gas desulphurization in the production process of sulfuric acid and fertilizer.

Cement industry: desulfurization of cement kiln tail gas.

Non-ferrous metal smelting: flue gas desulfurization of copper, lead, zinc smelting.

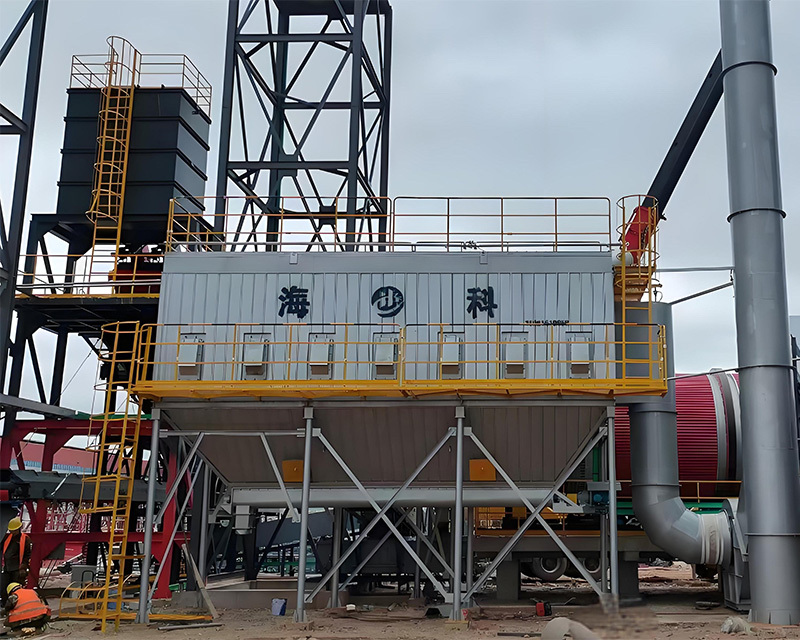

Haike Strength

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Strong strength, focused on professionalism

Development of energy-saving and environmental protection equipment and engineering general contracting

Professional design/research and development/production/installation team

Complete qualifications and strong technical strength

Quality assurance: independent research and development, establishment of domestic high-quality products

Striving for excellence, casting quality

Our main products include various types of combustion furnaces, dryers, dust collectors, powder concentrators, and more

Dry powder mortar production line, widely used in metallurgy, electricity, chemical industry, building materials

Waiting for the industry.

Haike Quality

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

Case Engineering

Specializing in the production, research and development, and sales of energy-saving and environmental protection equipment, widely used in industries such as metallurgy, electricity, chemical engineering, and building materials

keywords:

ONLINE CONSULTING

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

English

English Русский

Русский بالعربية

بالعربية